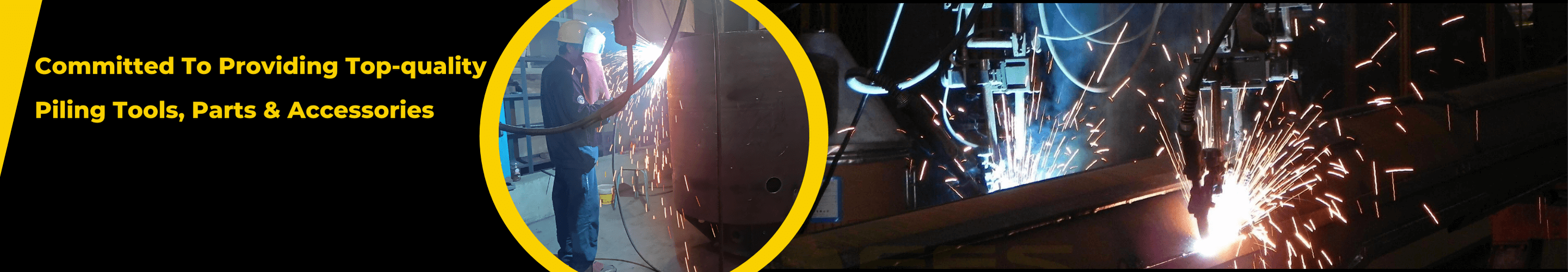

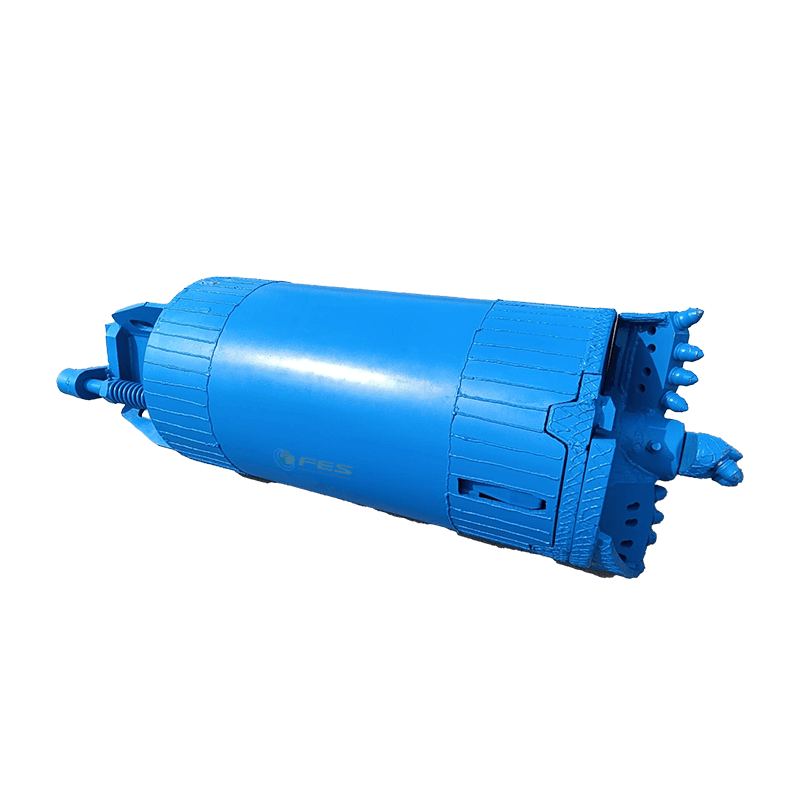

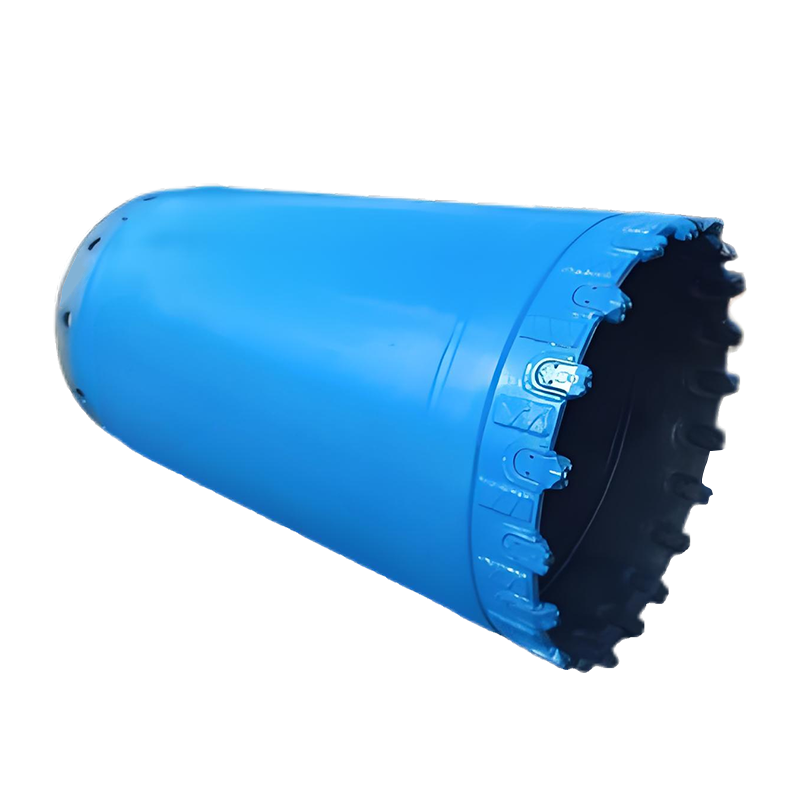

Desander

Desander is placed after the shale shaker and the degasser but before the desilter. Different from the shale shaker separating solids by screen, the desander removes the abrasive solids from the drilling mud by centrifugal force.

(1) High quality cyclone PU material with better abrasion resistance and longer service life.

(2) Explosion, water and dust proof electrical control panel with SIEMENS or Schneider components.

(3) Top brand vibration motors made by Italy OLI or US Martin optional

(4) Compact structure and flexible assembly

(5) Optional with or without shale shaker for flexible application.

(6) G force is adjustable up to 7.5G.

(7) Mechanical seal centrifugal pump realizes easy maintenance

| Model | FD-200D | FD-500D | FD-1000D |

| Description | Data | Data | Data |

| Capacity |

50m³/h (200GPM) |

120m³/h (500GPM) |

240m³/h (1000GPM) |

| Cut point |

25Micons |

40Micons |

40Micons |

| Mud cleaner |

GNZY753E-Y4NF |

GNZY753E-Y1S |

GNZY705E-Y2S |

| Vibration strength |

7.5G (adjustable) |

7.5G (adjustable) |

7.5G (adjustable) |

| Upper screen area |

1.35㎡ |

1.35㎡ |

2.60㎡ |

| Bottom screen area |

0.875㎡ |

0.875㎡ |

1.75㎡ |

| Desilter size |

4 inches |

10 inches |

10 inches |

| Cone number |

4pcs |

1pce |

2pcs |

| Centrifugal pump |

GNSB4*3A (11kW) |

GNSB6*5A(37kW) |

GNSB8*6A(55kW) |

| Total power |

14kW |

39kW |

59kW |

| Transport dimension (L*W*H) |

3103*2046*2637 |

3103*2050*2441 |

3780*2162*2612 |

| Operation dimension (L*W*H) |

3506*2054*3746 |

3506*2050*3721 |

4176*2162*3796 |

| Total weight |

2700kg |

2850kg |

3700kg |